(800) 748-5647

(800) 748-5647

Mirafi 160N Geotextile Fabric - 12.5' x 360' Roll Model: 160N-12.5X360Brand: Mirafi - TenCateSize: 12.5' x 360'Square Feet / Roll: 4,500Weight: 231...

View full details

Mirafi 160N Geotextile Fabric - 15' x 300' Roll Model: 160N-15X300Brand: Mirafi - TenCateSize: 15' x 300'Square Feet / Roll: 4,500Weight: 203 lbsFa...

View full details

New York NYSDOT - Separation Geotextile Fabric - Class 2 - Nonwoven - 15' x 300' Roll - 160N Model: 160N-15X300Brand: Mirafi - TenCateSize: 15' ...

View full details

New York NYSDOT - Subsurface Drainage Geotextile Fabric - Class 2 - Nonwoven - 15' x 300' Roll - 160N Model: 160N-15X300Brand: Mirafi - TenCateSize...

View full details

PNW60 Non-Woven Geotextile Fabric - Mirafi 160N Equivalent - 10' x 100' Roll Model: PNW60-10x100Size: 10' x 100'Square Feet / Roll: 1,000 Fabric...

View full details

PNW60 Non-Woven Geotextile Fabric - Mirafi 160N Equivalent - 10' x 300' Roll Model: PNW60-10x300Size: 10' x 300'Square Feet / Roll: 3,000Fabric S...

View full details

PNW60 Non-Woven Geotextile Fabric - Mirafi 160N Equivalent - 6' x 300' Roll Model: PNW60-6x300Size: 6' x 300'Square Feet / Roll: 1,800Fabric Specif...

View full details Case Study:

Case Study:

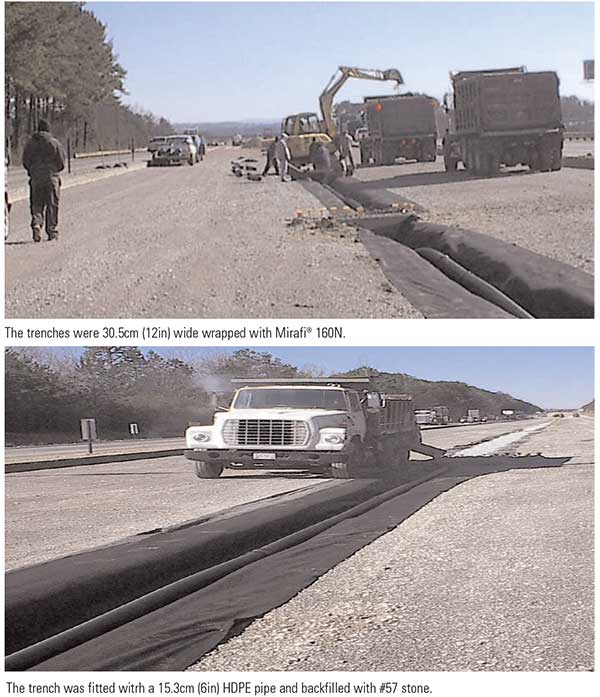

Mirafi 160N – Birmingham, Alabama

TenCate Mirafi® N-Series non-woven fabrics are stable fibers used for soil drainage and separation. This product is a combination of hydraulic and physical properties and is extremely durable. Made from polypropylene staple fibers it allows for a high rate of water flow while offering excellent soil retention. TenCate Mirafi® N-Series geotextiles are used in a variety of ways including roadway separation and subsurface drainage applications.

TenCate Mirafi® N-Series increases performance and offers excellent results while keeping costs down.

The Objective:

Interstate 20 which runs between Birmingham and Pell City, Alabama needed to be extended. The project required widening the 4-lane highway to a 6-lane highway along with adding a median and shoulder. The Alabama Department of Transportation's biggest challenge was the logistics involved for safety, the delivery of materials, and the work being performed in this area.

The Designing Process:

The original design included a grassy median with drainage outfalls, catch basins, and a 36-inch pipe connecting each catch basin along with a 24-inch outfall pipe to unload stormwater runoff from the median areas. The Alabama Dept. of Transportation wanted to keep the existing piping underground but add median drains and edge drains where needed. They had schematic drawings of the median and edge drains in the design, depending on the drainage plane of the pavement. Also, there was an E-layer of absorbent asphalt material to help in the drainage process of the subgrade to the median drains. When completed, the asphalt layer would be between 18-inches and 24-inches.

Construction:

The 7.5 feet wide Mirafi® 160N was wrapped around the 12-inch wide median drain trench. The trench was fitted with a 6-inch HDPE pipe and then backfilled with #57 stone. Using nails, the fabric was pinned to the subgrade and overlapped 24 inches onto the base. The 6-inch pipe was then attached to the catch basin through an 8-inch hole in the basin. The plan did not call for compaction for the drainage trench. The contractor set the elevation and was responsible for the grading, making the installation a much easier task.

For additional information, and CAD details please see the TenCate website.

Differences Between Landscape Fabric And Drain Field Fabric:

The biggest difference between landscape fabric and drain field fabric is how the products are used. Landscape fabric is manufactured for use in landscape and garden designs. This product aids in retaining soil and deterring weeds. Once the fabric is in place, it's topped with a ground cover such as cedar chips or decorative stones

Drain field fabric, on the other hand, is used to protect sand filters in drain fields from soil that would easily clog the drains. Drain field fabric is lightweight in which one square yard will weigh under one ounce. Landscape fabric and drain field fabric comes in a variety of widths to help in different projects. The most common sizes are 36, 54, and 120 inches and both are in the group known as geotextiles.

Geofabric Geotextiles are specifically designed to increase the stability of surrounding soil. By doing so, they improves drainag and helps to control erosion. This is not a new technique, the ancient Egyptians placed fabric into the ground with vegetation. Unlike the fabrics used by Egyptians, modern manufacturing produces a non-biodegradable fabric that will last a really long time in small gardens as well as large construction projects. Geofabric comes in two kinds, woven and non-woven. The non-woven is used in drain fields, for erosion control, and as an overlay for pavement. The woven fabric offers a great deal of strength and durability but is not great for filtration needs.

Drain fields must be able to breathe in order to operate properly Laying drain field fabric between the soil and stones, the fabric will keep out excessive soil particles and sediment. Sediment can seriously obstruct the drain field's filtering abilities. This is precisely why this fabric is lightweight in comparison to landscaping fabric. That said, landscaping fabric has been used in drain fields but it is not recommended. Drain fields require a fabric that not does exceed a weight of 2 ounces per square years.

The Benefits Of Drain Field Fabric:

Your standard drain field consists of a trench of rock with a perforated pipe on top of it. The pipe is then covered with the drain field fabric and then a layer of crushed stone. Another layer of fabric is applied and then a layer of soil that is no less than 6 inches deep. The benefits of a Drain Field Fabric Filtration in a drain field is the interplay between the soil and flow of water. The lightweight drain field fabric facilitates the interaction of soil and water flow without the buildup of sediments. Absorbency stays in the fabric due to tiny holes giving it an effect of a reverse filter for the surrounding soil. Drain field fabric will also deter the growth of roots that could easily damage the drain field. This is similar to what landscape fabric does in blocking weeds.

Landscape fabric is heavier than drain field fabric and when laid on the surface of the soil it will block weed growth, control erosion, and gives an even look for a decorative appearance. Geofabric products are manufactured as woven or non-woven products. The woven fabric offers a greater longevity and durability for garden use. Landscape fabric also allows water and air to move throughout the soil which means the soil temperature will not alter much and protects plants with delicate root systems.

Landscape fabric is the best choice for sidewalks, decks, and placed in gardens that have decorative ground covers such as stones, rocks, or mulch.

The Limitations Of Landscape Fabric:

Landscape fabric does have its limitations. This is a geofabric that is designed to be photodegradable so it will not harm the quality of the soil. Photodegradable means it is capable of being decomposed by light, especially sunlight. Also, seeds and particles of dirt do land in the ground cover, so chances are you will still have to weed. This fabric is also more expensive than plastic but plastic will not let in water or air. You could try drain field fabric in place of landscape fabric but it's really not an ideal choice for above-ground purposes.

One of their major concerns was water run-off from storms that would potentially harm the surrounding areas. Typically, asphalt parking lots, oils, and other contaminants will mix in with stormwater and add to contaminating adjacent areas as well. The challenge for the Living Desert Zoo & Gardens was in constructing a paved system where the water could be collected and used for their watering needs and not become contaminated by harmful elements. The areas that border the animal enclosures and the parking lot needed retaining walls that would also blend with the natural surroundings.

Note: If you are looking for a slighting stronger fabric the Mirafi 180n is the next model up in strength and has a slightly lower flow rate.